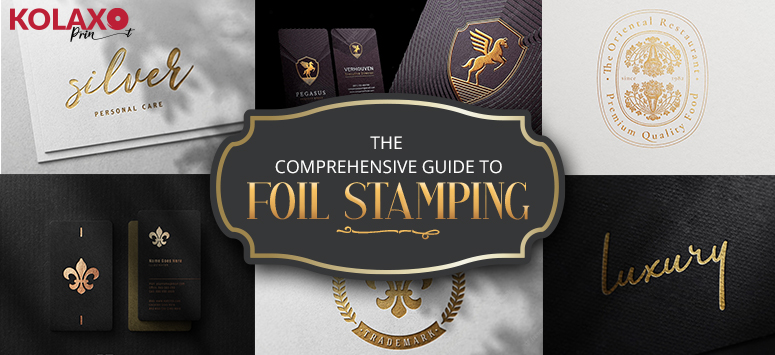

The Comprehensive Guide to Foil Stamping

Foil stamping is a popular method for creating a unique look. The Foil can create a metallic look or even a colorful one. It's also possible to use it with other techniques, such as embossing and foiling on leather or wood.

Foil stamping is a unique and visually appealing way of adding patterning to any printed material. It can be used on many different materials, including fabrics and paper, but it is prevalent in the fashion & beauty industry.

Foil stamping is a metal printing process that utilizes very little ink and heat to create an aesthetically pleasing surface design. It is similar to hot stamping, except the metal plates used are coated with Foil rather than ink.

Let's explore further foil stamping:

Stamping Process:

The fundamental foil stamping process begins with a metal plate that has been etched or designed to create the desired image. It can be any shape, but it is usually round and about 2 inches in diameter. The plate adheres to the desired area on the piece, then heated and pressed onto a foil base material being stamped.

Once the plate is created and adhered to the desired area on the piece, it is heated and pressed onto the Foil. The heat from this process causes it to melt while still adhering to any sites that have been previously stamped.

The stamping process can be done in a variety of ways depending on what you are trying to achieve with your design:

- With multiple designs or images stamped onto each side of your item (which creates a beautiful cameo effect)

- Stamping one image only onto one side of your item (this will make an eye-catching focal point)

Foil stamping is the application of metallic paper onto various surfaces to create a form of branding. It can be used for small- or large-scale projects, such as packaging or signs.

Foil Stamping process:

- The first step in foil stamping is to heat and pressure the base material. It can be done by hand or machine, but in either case, a pressurized chamber is used to apply pressure on the stamping surface.

- The second step involves adhering to Foil to your product. To perform this, heat and pressure attach the Foil to the stamped base material.

Foils Come in Either Rolls or Sheets:

In general, foils come in either rolls or sheets. Rolled Foil is a large sheet of metal repeatedly rolled until it becomes flat. It can be cut to size and used on smaller areas, but it will not hold detail as well as rolled Foil.

Sheets of Foil are thinner than rolled Foil and are easier to handle when working with them because they don't require any manipulation before use. They do not hold detail well, though; you will need more time when creating your design if you choose this option.

Foil comes in different thicknesses you'll find everything from super thin 0mm through 3mm depending on what project needs doing!

Different colors & properties of Foil:

You'll also find different colors ranging from white through gold; these all have other properties that affect how well certain types work for specific projects, for example, metallic finishes won't show up well against darker fabrics because their reflective qualities make them appear duller than other materials which could cause problems when trying to create specific effects using paints.

Foils can be pigmented or metalized when specific colors are desired, and metallic-looking foils are wanted. Pigmented Foil is made from a spot of ink mixed with a polymer to create the image. Metallized Foil is produced by electroplating another metal onto the surface of the Foil and then washing out any excess before using it on your project.

Hot Stamping Process:

Hot stamping involves using one of two methods for applying the Foil to the product. Hot stamping is a process that uses heat and pressure to apply the Foil to the product.

One method involves using an inkless hot stamping machine, which applies a piece of Foil by pressing it down against anvils that are heated above 500°F (260°C). The second approach involves using an ink bucket that has been filled with a thermoplastic solution and then placed into a heated chamber where it's agitated by water or steam jets until it melts and allows you to remove your design on top of your product.

Conclusion:

To sum up, foil stamping applies metallic paper using a classic tool called the platen press. This technique involves adhering the plate to an object that is then heated and pressed into place with pressure. In general, foils come in either rolls or sheets, depending on what type of design you want to create with your piece of printed material. Foils can be pigmented or metalized when specific colors are desired, and metallic-looking foils are wanted. The resulting look of this combination can provide a unique and visually appealing design for any piece of printed material